- Joined

- Nov 10, 2011

- Messages

- 544

- Reaction score

- 2

I cut a deal with Blackhorse. He agreed to make me a knife and I agreed to make him a Morta pipe.

He held up his end of the bargain by making me a beautiful knife with a custom carved Snakewood handle.

I thought it might be fun to do a photo essay to document my process as I hold up my end of the bargain.

1) Mark out the pipe on a piece of Morta (my last one )

)

2) Cut off some of the waste with the band saw

3) Square off the end of the accent piece and cut off a coin

4) Square up a piece of Faux Ivory for the stem extension

5) Glue the accent piece on

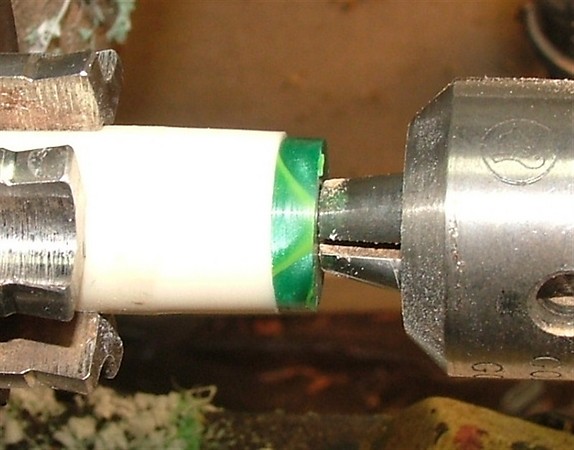

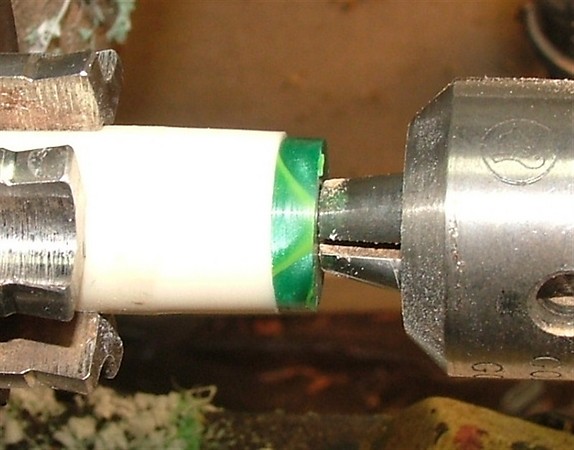

6) Square up the end and drill out the mortise

7) Drill the draft hole in the Morta

8) Rotate and drill the tobacco chamber

9) Start to form the outside of the bowl

10) Form the stem extension after the epoxy is dry

11) Form the tenon to accept the stem extension

12) Glue on the stem extension

13) Time to work on the stem. Drilling out the draft hole.

14) 1/16" bit for the last 1/4"

15) Epoxy the tenon into the stem. I chose Stainless Steel tubing because the shank is so small.

16) Form the outside of the bowl with a sanding disk

17) My progress so far

18) The stemmel is done. Time to shape the stem

19) Forming the slot

20) Doesn't look like much now

21) Clean up the slot with a file

22) Almost there. Just need to refine the stem and give it a little bend.

23) Finish sanding and rusticate the bowl with a wire wheel and it's done

He held up his end of the bargain by making me a beautiful knife with a custom carved Snakewood handle.

I thought it might be fun to do a photo essay to document my process as I hold up my end of the bargain.

1) Mark out the pipe on a piece of Morta (my last one

2) Cut off some of the waste with the band saw

3) Square off the end of the accent piece and cut off a coin

4) Square up a piece of Faux Ivory for the stem extension

5) Glue the accent piece on

6) Square up the end and drill out the mortise

7) Drill the draft hole in the Morta

8) Rotate and drill the tobacco chamber

9) Start to form the outside of the bowl

10) Form the stem extension after the epoxy is dry

11) Form the tenon to accept the stem extension

12) Glue on the stem extension

13) Time to work on the stem. Drilling out the draft hole.

14) 1/16" bit for the last 1/4"

15) Epoxy the tenon into the stem. I chose Stainless Steel tubing because the shank is so small.

16) Form the outside of the bowl with a sanding disk

17) My progress so far

18) The stemmel is done. Time to shape the stem

19) Forming the slot

20) Doesn't look like much now

21) Clean up the slot with a file

22) Almost there. Just need to refine the stem and give it a little bend.

23) Finish sanding and rusticate the bowl with a wire wheel and it's done