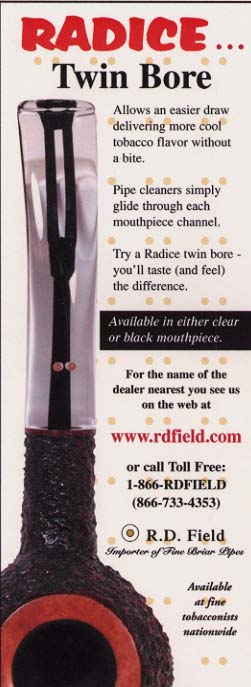

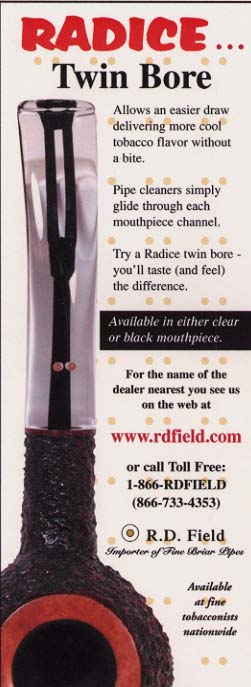

I been hearing controversy over how the Radice Twin Bore's were constructed. Some are saying that it did in fact have a "V" connecting the two draw holes at the button while others say it doesn't. Now being that I have no experience with Radice twin bores except for ones I've seen and one I own I ask you for your experience. From what I've seen and the limited research I've done I find that they may have been done both ways. Also let me add that the ones I've had in my hand that were "V'd" so to speak were done horribly and unprofessional in my eye and I don't think Mr. Radice would have done that. Now here are two documents showing the "V" in a clear stem and two separate holes in a black. Did they in fact make them both ways or was the clear stems the only ones to use the "V"?

![[3-Size Set] Copper Pipe External Cleaner for Drill, Clean 1/2, 3/4, 1-in Copper Pipes & Tubes for Soldering, 3 Tube Cleaning Brushes,Steel Pipes Tubes and Fittings,with Wire Bristles & 1/4” Shank](https://m.media-amazon.com/images/I/3173meSSjsL._SL500_.jpg)

![[3-Size Set] Copper Pipe Cleaner for Drill, Clean 1/2, 3/4, 1-in Copper Pipes & Tubes for Soldering, 3 Tube Cleaning Brushes, Model InerLok050, 075, 100, w/ Stainless-Steel Wire Bristles & 1/4” Shank](https://m.media-amazon.com/images/I/41QVxunlqML._SL500_.jpg)

![[4PC Bundle] 3/4-Inch Copper Pipe Cleaner Set for Power Drill, 3/4” Tube Cleaning Brush, Cleans Copper Pipes Tubes and Fittings for Soldering, w/ Stainless-Steel Wire Bristles & 1/4” Shank](https://m.media-amazon.com/images/I/41TyAXGngCL._SL500_.jpg)