Kyle Weiss":byp5tn8v said:

With that said, Kurt, where's a good place for folks to get proper bits for powered use?

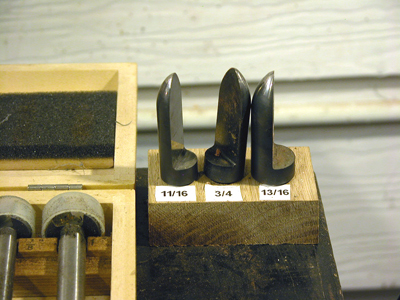

Downie pipes apparently are made with these:

Those were made by Brad Pohlmann. They are the current gold standard for freehand drilling tobacco chambers. Every few years he finds some time to make a new set and offer them for sale. His current run is going on now, but since I have a set in the two sizes I use most, I have not partaken of this round. I did not look at the price for this production period, but the last one was about the cost of a drill press - each.

Now, I want to make it clear. This is NOT the one and true way to drill a tobacco chamber. Is is

A way. And when I say "freehand drilling", that means that the pipe is fully shaped before a single hole is made. It is a very advanced technique that requires a lot of practice and more than a few screwups. Essentially you shape the pipe in it's entirety, then drill the mortise, airway, and tobacco chamber. It is, frankly, not for everyone. It's really not even for me. I actually don't care for the method, though I do use it from time to time as necessary. OR when I feel like pushing my envelope. Others use it every day. They've earned my respect for that.

The majority of my pipes are drilled with a silver and deming bit that has had the tip reground to the proper shape. I could just as easily use a spade bit, and sometimes I do. It depends on what the pipe shape is, and what sort of chamber I want. I have found the reshaped silver and deming bits to provide the most consistent results and best finish inside the chamber, but the spade bits are doggone inexpensive. Really it boils down to personal choice - what can you afford, and how much time are you going to invest in making your tooling (or cash to buy it).

Kyle Weiss":byp5tn8v said:

I love all the posts where I suffix things with "and you might die".

If you look hard enough on that forum, you will find my method for reshaping silver and deming bits. It's dangerous and stupid. Don't look for it. You have been warned. I accept no responsibility to your estate.

Kyle Weiss":byp5tn8v said:

...are some vehemently against using "traditional" spoon bits versus custom-made, very expensive bits, or is the matter a closed one among everyone? There has to be more options, I've tried doing a LOT of research on what tools everyone uses, and since I don't have the space or $5,000 to drop on custom lathes, drill presses and the like. there's got to be a way to do this. I'm not Rad Davis, nor will I ever be.

*shrug*

The standard bit for beginners is the reshaped spade bit. It's solid, it works, it's inexpensive, and it's not complicated. A lot of very experienced pipe makers use reshaped spade bits that cost them a $1 at the local hardware store, and 15 minutes to reshape. I use them all the time, and I've been doing this for over 10 years.

I also don't own a crapload of high precision and custom tooling, outside of what I've made myself. If you want I can list my daily tooling, which I think would surprise a lot of people. Suffice to say, I don't think I have anywhere near $5000 invested in the totality of my tooling.

Pipes can be made any number of ways. But if I make a suggestion on what NOT to do, please believe me, it's because I want to save someone time or health. Some things I see suggested on pipemakersforum.com are just downright dangerous, and it's those things I encourage folks not to do.

Kyle Weiss":byp5tn8v said:

Another option, modified spade bits:

...but again, I'd have to track down a metal worker to do this for me. A much higher likelihood when I get to the point I want to try drilling my own chambers.

If you have access to a bench grinder or belt sander, you can make these. If not, PIMO (as you've found) offers these for sale. If you're looking, I suggest the PIMO bits. They are very good, and I still have the original set I bought all those years ago - along with the book. For the beginner, PIMO has all teh tools you need, and they're not expensive in the least.

Kyle Weiss":byp5tn8v said:

Overall, part of the reason why I don't post on pipemakersforum.com is there seems to be only one way to do things, the juggernaut carver's way, or the wrong way. Perhaps there's some truth hiding in the power trips, egos and arguments on there, but the conflict does little to help out those who are either starting out or try to make do with what they have.

It's only discouraging to newbies and those who's immediate goal isn't to produce a $600 stunner pipe at Chicago Pipe Show.

By and large, we are a supportive group that is very open to alternative methods.

We will make suggestions, however, if we see inefficiencies in process or tooling. So if you say you want to use nothing but hand tools, you will get a reply or two that indicates that a drill press, at minimum, would be a good investment. BUT, nobody will hang you for it. If, however, you say you want to make two pipes a day and go full time, and sell pipes that cost $1000, but are not willing to listen when a pro (or dedicated semi-pro) tells you to reconsider your methods, then you tend to get ignored or berated. I suppose it's all in the presentation, as with most things.

Even if you want to use mostly hand tools, there are those of there that are just geeky enough to have done that and can offer advice on how to best do such things.

![[3-Size Set] Copper Pipe Cleaner for Drill, Clean 1/2, 3/4, 1-in Copper Pipes & Tubes for Soldering, 3 Tube Cleaning Brushes, Model InerLok050, 075, 100, w/ Stainless-Steel Wire Bristles & 1/4” Shank](https://m.media-amazon.com/images/I/41QVxunlqML._SL500_.jpg)