R.A.

Well-known member

- Joined

- Feb 9, 2011

- Messages

- 125

- Reaction score

- 1

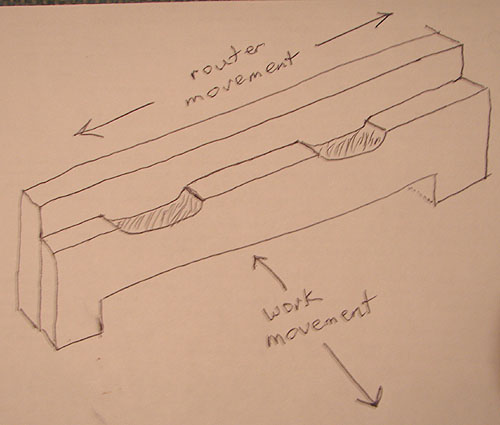

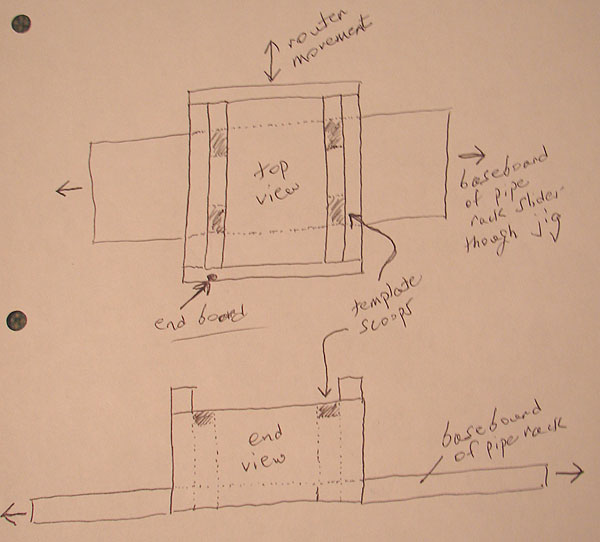

Ok we all seen lots different pipes racks, and ways the pipes rest in them, My question is about the one where the bowl rest in a rounded egg shaped scooped from the wood, like the one in this link

http://www.bigashtray.com/content/00/01/49/82/52/userimages/Smoking%20pipe%20stand%2009/Humidor-and-pipe-holder.jpg

I would like to try to build a little rack but no idea which tool I need to duplicate this scoop out, I,m not trying to build this exact item but I would like the one I want to build to have the scoops to sit the pipes in

any ideas?

http://www.bigashtray.com/content/00/01/49/82/52/userimages/Smoking%20pipe%20stand%2009/Humidor-and-pipe-holder.jpg

I would like to try to build a little rack but no idea which tool I need to duplicate this scoop out, I,m not trying to build this exact item but I would like the one I want to build to have the scoops to sit the pipes in

any ideas?

![[3-Size Set] Copper Pipe Cleaner for Drill, Clean 1/2, 3/4, 1-in Copper Pipes & Tubes for Soldering, 3 Tube Cleaning Brushes, Model InerLok050, 075, 100, w/ Stainless-Steel Wire Bristles & 1/4” Shank](https://m.media-amazon.com/images/I/41FEqUv4rNL._SL500_.jpg)